Some applications in video

Ludovic principles |

|

The GLOBAL analysis with Ludovic : some results |

|

The process optimization |

|

The LOCAL analysis with XimeX-TSE : some results |

|

|

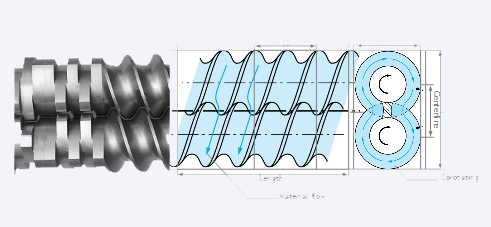

Le procédé bivis |

Compoundage en bivis |

SC-Consultants proposes two numerical simulation software dedicated to the corotating twin screw extrusion process. Ludovic and XimeX-TSE offer a complementary analysis of the extrusion process.

Both software are used in industry to bring an indeep understanding of the process mechanisms, and thus the capability to reduce the R&D costs by streamlining the real tests.

Ludovic is a valuable supplement to experimental work that can provide insight into optimization, troubleshooting, and scale-up challenges of melt compounding and reactive extrusion processes. The accessibility of the software to users without extensive simulation experience and rapid computation of results make Ludovic a powerful alternative to more resource-intensive simulation approaches. Simulations can be tailored to different levels of detail and sophistication providing valuable and rapid feedback throughout the development process.

Ludovic proposes a global overview of the twin screw extrusion process and a global analysis of the material behaviour evolution all along the process. Ludovic is thus especially useful for designing the process (including scrw profile design), optimizing the operating conditions and performing scale up/scale down actions.

Thanks to the powerful 3D technology, XimeX-TSEproposes a very thin focus son active-mixing element in a twin screw. XimeX-TSE brings a very detailed thermo-mechanical analysis to compute and estimate the mixing capabilities of the screw elements. It helps in determining the kind of mixing effect on a specific zone of the screw. The kind of mixing (dispersive, distributive, elongational...) is easily identified by comparative analysis.

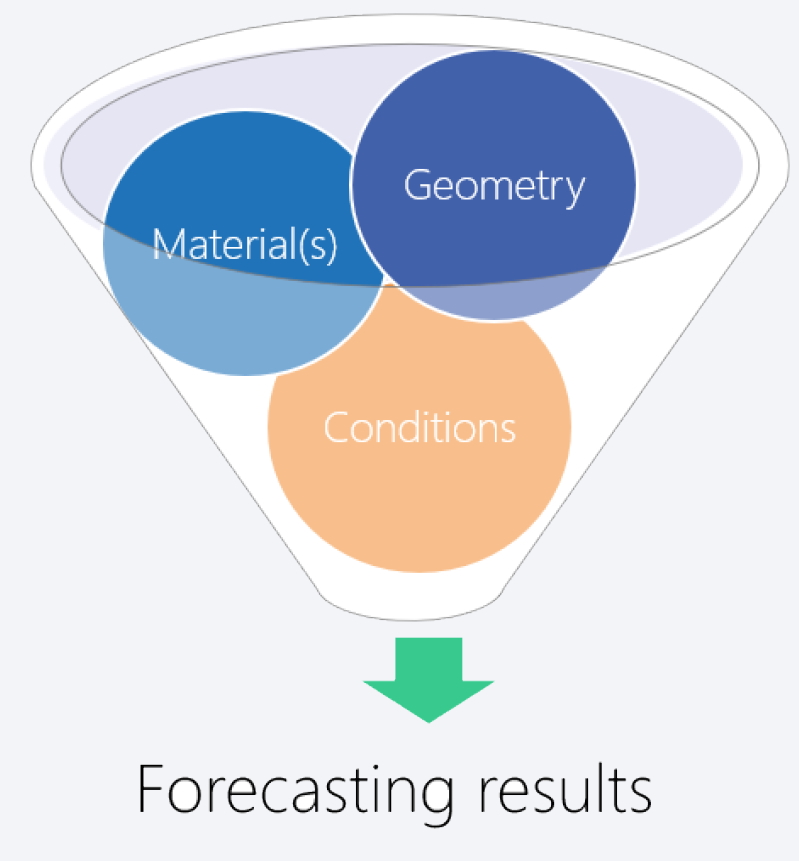

With the Ludovic® software, the main target of the user is to handle the whole process components to offer a global analysis (in a few seconds of computation) and then open the black box. Such analysis helps in figuring out the main twin screw mechanisms. The simulation input data describe the process main stages, with:

the extruder geometry/screw design

the material characteristics

the operating conditions

The simulation results describe the material evolution all along the process and the energy balance of the process.

The input data you use in Ludovic® are 100% customizable. As a consequenc, Ludovic® is used for:

any kind of extruder (no limitations of size/brand)

any kind of screw elements (a generic library is procided into the software)

any kind of material

Ludovic® provides lots of results. First serie of results is dedicated to the material evolution with meaningful results displayed all along the screw profile (for a really good overview). Other results are dedicated to the process efficiency. They help in comparing different potential configuration of your twin screw process.

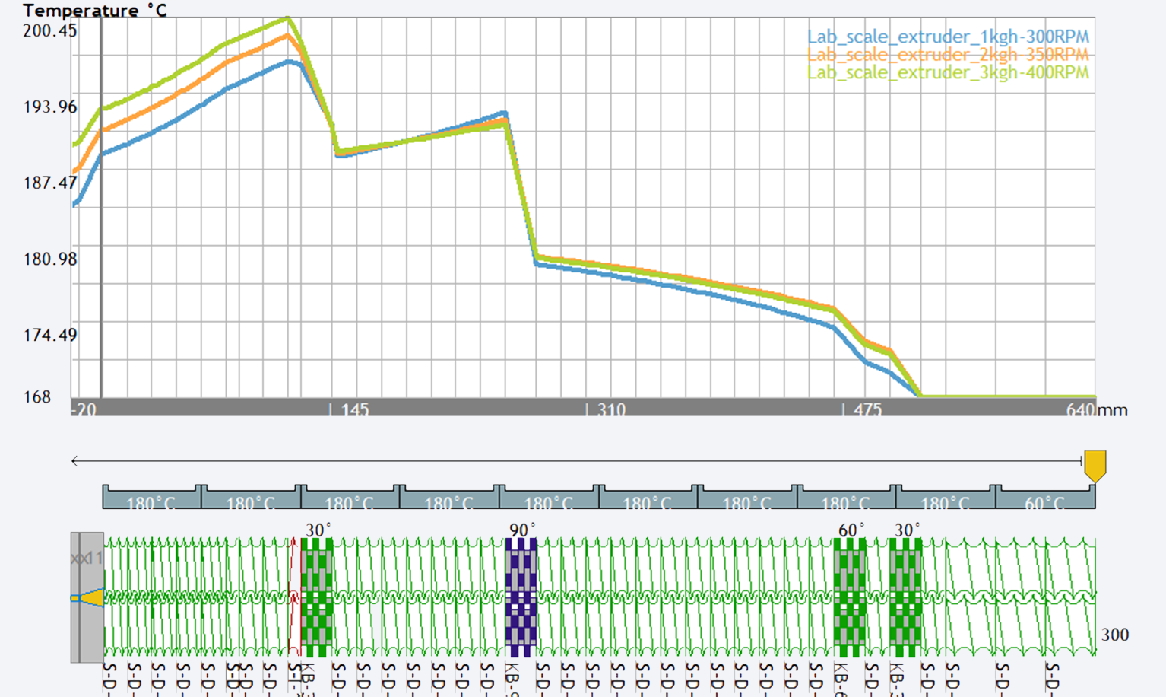

Many thermo-mechanical data are plot along the screw profile to analyze the material behaviour evolution (opposite picture describes the evolution of the material temperature for different operting conditions). Those results are computed while considering the impact of the screw profile design, the material and additives characteristics and the applied operating conditions.

Among the available results :

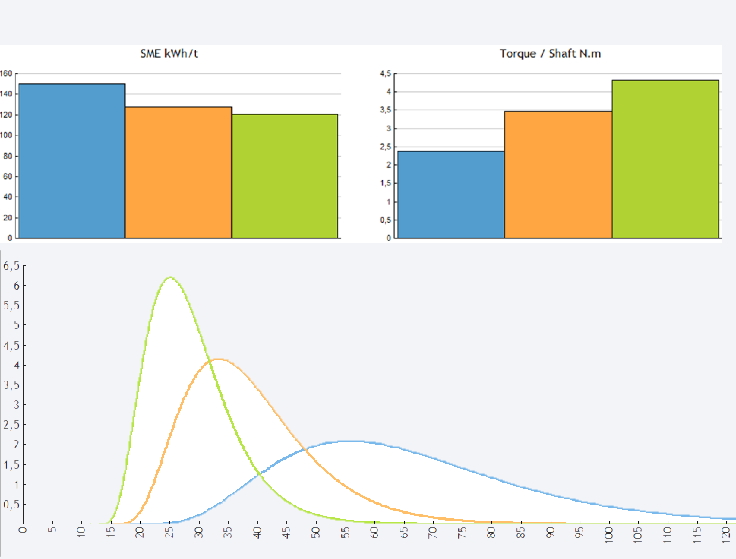

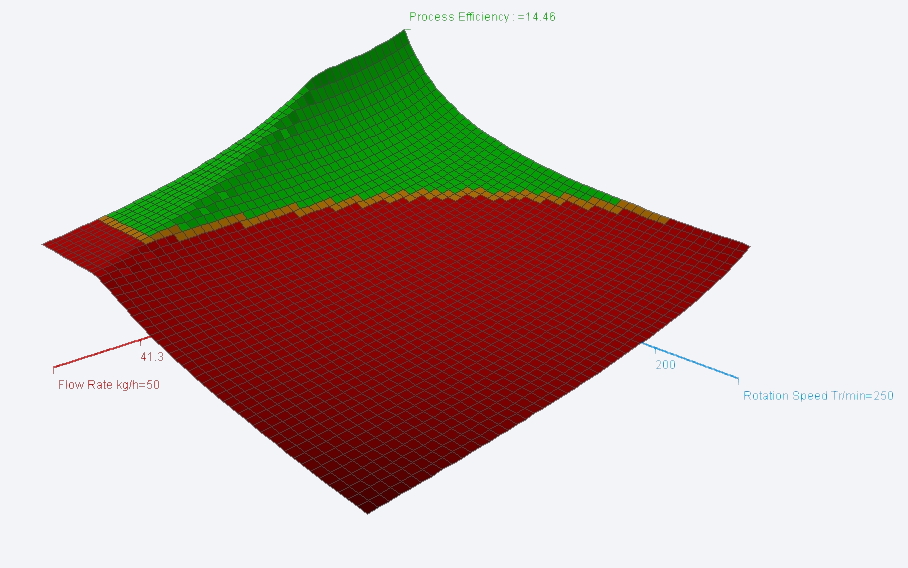

For the process mixing efficiency, different results are also provided by Ludovic®. The opposite picture shows as an example, the SME (Specific Mechanical Energy), the torque and the RTD (Residence Time Distribution) for different operating conditions.. Ludovic results help in figuring out the material evolution and also the requested energy to run the process.

Checking the process mixing efficiency

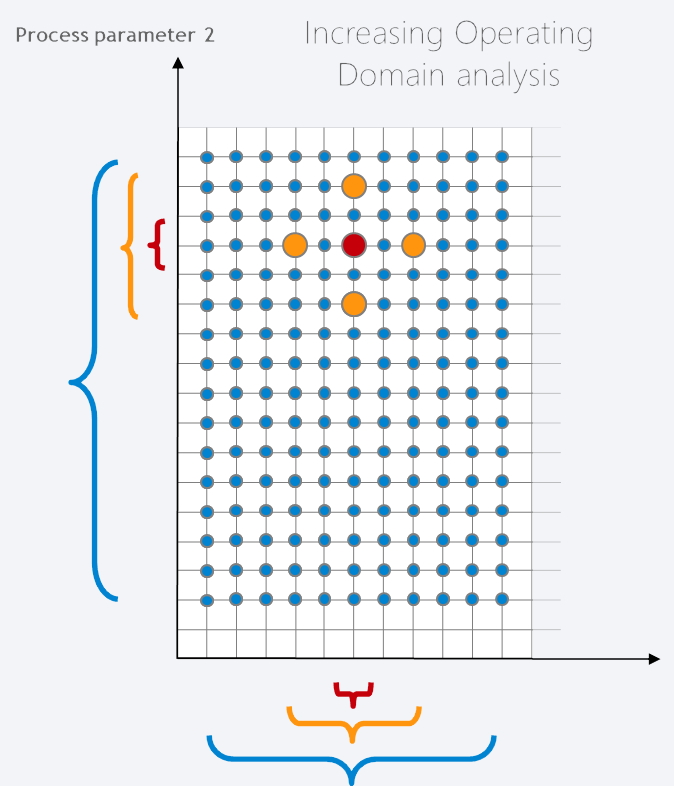

Different tools (included into the Ludovic package)allows to get a process indeep analysis, with:

The main industrial applications (for twin screw) are then easier by using the Ludovic software, with:

Ludovic allows thus to virtually prepare the trials/experiments you will run on your machine. This way,time to market, and R&D/industrialization costs are reduced.

...for industrial applications

Thanks to our complete package (including training and services), it is now easy to maximize the ROI (Return on Investmen). SC-Consultants proposes different kind of licenses (temporary/Permanent, Single seat/multi-seat license).

The Ludovic software license are provided with: :

All those services provides a fast handling of the sofware with a very short and adapted learning curve.

The Ludovic software is developped and distributed by Sciences Computers Consultants. It comes from research work performed by famous and renowned laboratories : the CEMEF (Mines ParisTech) and the INRAE.

There are thus many application fields for the Ludovic software:

Ludovic principles |

|

The GLOBAL analysis with Ludovic : some results |

|

The process optimization |

|

The LOCAL analysis with XimeX-TSE : some results |

|

|

Le procédé bivis |

Compoundage en bivis |