Controlling the thermo-metallurgical properties of the alloy during the ingot casting

The Solid software performs an indeep analysis of the solidification process. In this application case, the Solid software focuses on the ingot casting.

Controlling the thermo-metallurgical characteristics of steel ingot is a challenge as they determine the properties of the final workpiece.

Indeed, during the solidification process, many parameters (such as mould geometry, process conditions, alloy composition…) have a strong impact on those characteristics. The competition between the growth of columnar and the sedimentation of the equiaxed grains defines the solidification structures of the ingot. And the solidification structures in turn affect the macrosegregation of alloying elements.One of the features of the Solid software is computing the sedimentation of equiaxed grains, to predict the thermo-metallurgical properties of the final ingot. Such simulations thus help in optimizing the final product .

Impact of process conditions on the alloys

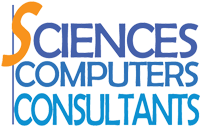

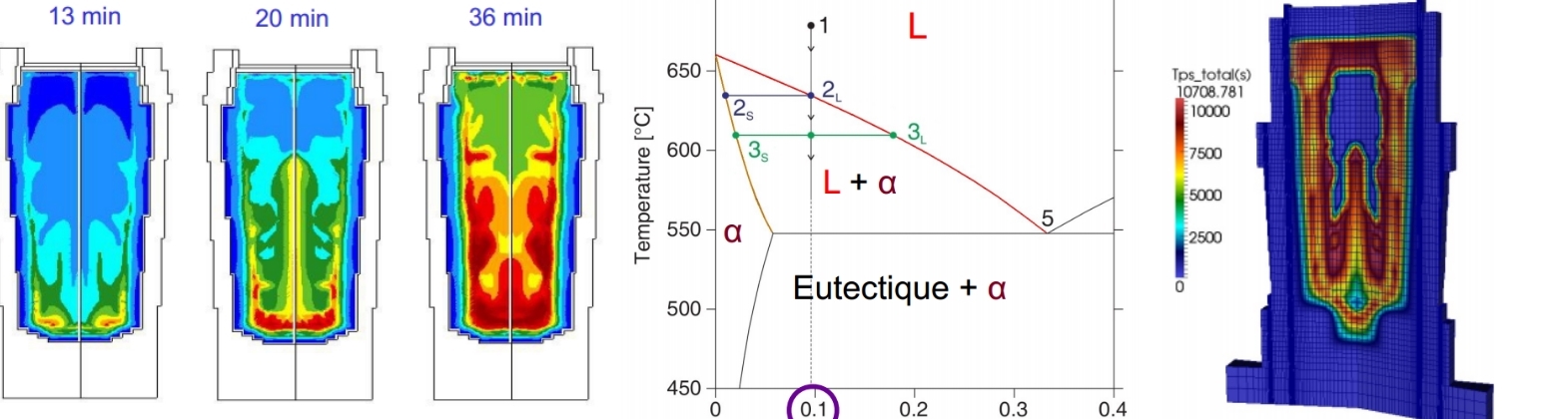

This case is a 2D simulation of the solidification of a cylindrical 6.2 tonnes steel ingot. The cast steel is a ternary Fe-C-Si alloy, with 1.01wt.% carbon content.

This application is used to showcase the solidification models used in the SOLID software: the nucleation and growth of grains, the formation of the solidification structures, and their influence on segregation of the alloying element (carbon). In addition, the model takes into account the impact of filling and process conditions such as the hot top.

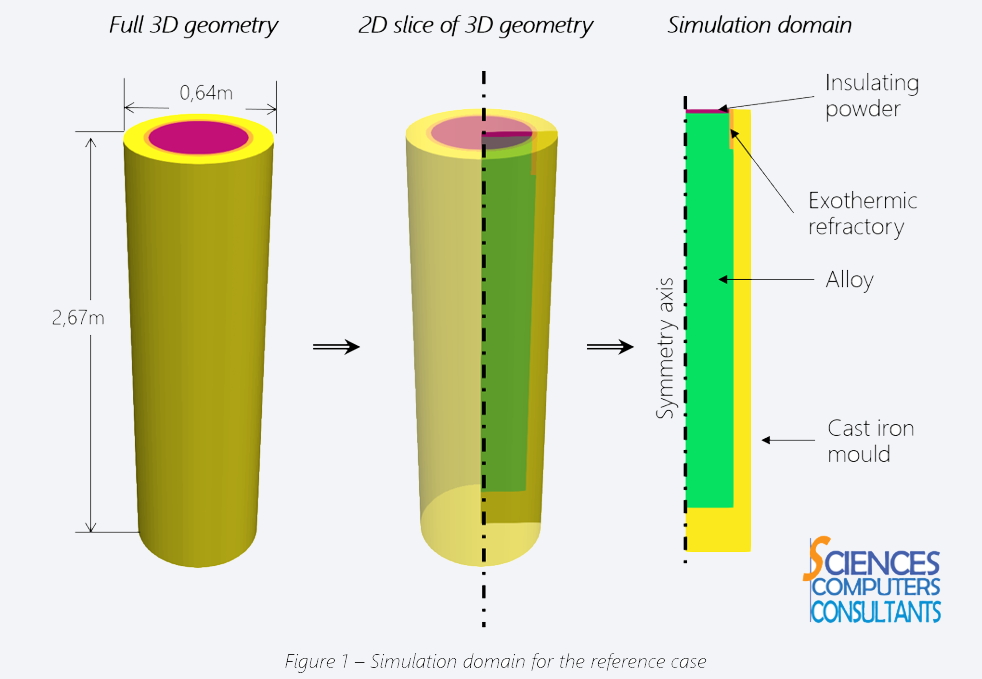

Changing parameters such as the filling rate or removing the exothermic properties of the hot top refractory affect the solidification and therefore the final macrosegregation. In this way, the Solid software shows the impact of process parameters on segregation and allows the user to easily test and compare different configurations.

Among the tested configurations:

- Removing the exothermic properties of the hot top leads to more intensity of positive segregation

- Reducing the filling rate by half has different effects, like increasing the grain density and reducing the size of negative segregation zone

- Comparisons of the different configurations a detailed in the following pages

Some results

As Solid is a 2D software using axi-symetry model, results are presented according to the simulation domain, used for the reference case.

The following results are then presented that way:

|

|

Filling time influence

The Filling Time has a strong impact on the solidification process (on both solidification structures and segregation). Increasing the filling time, makes the columnar thicker. When doing the inverese (reducing the filling time), columnar thickness is reduced. This is typically the kind of relationship between process, time, temperature and micro-effects that the Solid software can describe. |

|

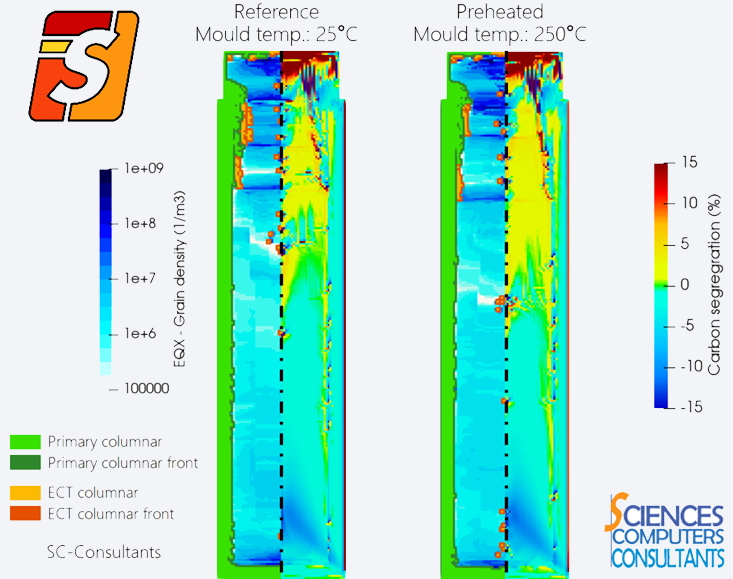

Mould Temperature

The temperature of the mould during casting can influence the cooling of the ingot. This is assessed by comparing the reference simulation with one where the cast iron mould is preheated at 250°C (instead of 25°C for the reference). The results (opposite figure) show that with the preheated mould, the columnar thickness is slightly smaller, as the cooling rate for the columnar was lower. The overall segregation is similar, even if the positive segregation seems more intense at the top of the ingot. |

|

More results

This application has been designed for showcasing the Solid software capabilities and main results. For some more details, you can contact us for downloading the full paper here

Solid: for a digital analysis of ingots casting process

Solid is today a real solution for developping and optimizing your projects. It offers a cost-effective solution for replacing the expansive trials. Solid is available as on premise license (different suited packages are proposed) and consulting services.

Visit our websites for more details about it at